à¤à¥à¤·à¥à¤¤à¤¿à¤ तॠवरà¥à¤à¤¿à¤à¤² à¤à¤ªà¥à¤à¤® लिफà¤à¤°

à¤à¥à¤·à¥à¤¤à¤¿à¤ तॠवरà¥à¤à¤¿à¤à¤² à¤à¤ªà¥à¤à¤® लिफà¤à¤° Specification

- वापर

- LIFTING DIES, MOULD, STEEL PLATES/BLOCKS

- अट

- नवीन

- उचलण्याची क्षमता

- किलोग्रॅम (किलो)

- उत्पादनाचा प्रकार

- Horizontal to Vertical EPM Lifter

- उर्जा स्त्रोत

à¤à¥à¤·à¥à¤¤à¤¿à¤ तॠवरà¥à¤à¤¿à¤à¤² à¤à¤ªà¥à¤à¤® लिफà¤à¤° Trade Information

- Minimum Order Quantity

- 1 तुकडा

- पुरवठा क्षमता

- प्रति महिना

- वितरण वेळ

- दिवस

About à¤à¥à¤·à¥à¤¤à¤¿à¤ तॠवरà¥à¤à¤¿à¤à¤² à¤à¤ªà¥à¤à¤® लिफà¤à¤°

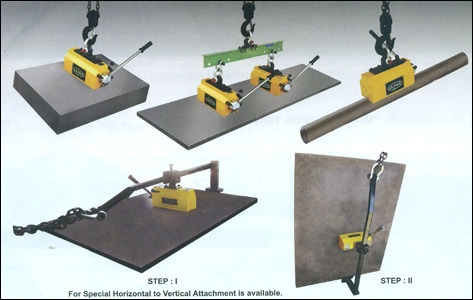

We are a noted name in the market engrossed in manufacturing, exporting and supplying an assorted range of Ultra brand Horizontal To Vertical Epm Lifter. This lifter is meticulously manufactured by utilizing cardinal quality components with the aid of sophisticated techniques as per the standards penciled by the industry. Highly acclaimed in ship building industry, the provided lifter is ideal for handling single plate in stockyards. Easily accessible in different sizes, the offered Ultra brand Horizontal To Vertical Epm Lifter can be availed at economical prices.

Features:

- Rugged design with user friendly operation

- Easy to operate with longer service life

- Requires less maintenance and easy handling

- Smooth functioning for fast and quick execution

- Equipped with excellent quality components and sophisticated control systems

- Needs less energy for the smooth operationElectro permanent magnets designed for handling in vertical or horizontal position

- Wirelessly operated and used for lifting & transporting heavy pipes or plates within the shop floor

- Consists of an electro-permanent lifting magnet body, maintenance-free batteries and a special remote controller

- Does not require power supply at the time of operation

- Intelligent fail safe technology never lets things fall

- No damage to the work piece being lifted

- Equipped with a safety control sensor to detect whether the EPM is suspended in air or not and avoids demagnetization of the EPM in suspended state

Application:

- Mainly used for handling of steel plates, blocks, press moulds

- Utilized as hoisting devices in factories, docks, warehouses and logistic industry

- Improve working condition and increases work efficiency

- Stocked with powerful batteries and remote control that can control the EPM

- Requires only one operator and can move large and heavy work piece safely & easily

OPTIONAL UNITS :

- Radio Remote Control - Operates from a convenient distance all the function i.e. MAG / DEMAG / Inching.

- ADPREM - Accidental Demagnetization Prevention Mechanism.

- Disable the demagnetization cycle when carrying load.

DESIGN :

- Designing of EPM plate lifter depends upon minimum and maximum size of plate

- Crane Capacity

- Weight of Plates.

| Plate Dimensions | Plate Thickness | No of Magnets | Rated Capacitymm | |||

| Length (mm) | Width (mm) | Kg | ||||

| Min | Max | Min | Max | |||

| 1500 | 6300 | 500 | 2500 | 4 - 35 | 4 | 4500 |

| 3000 | 12500 | 500 | 2500 | 4 - 30 | 5 | 7500 |

| 3000 | 12500 | 500 | 3500 | 4 - 30 | 5 | 10000 |

| 3000 | 12500 | 500 | 3500 | 4 - 40 | 6 | 12000 |

| 3000 | 12500 | 500 | 3500 | 4 - 50 | 8 | 17500 |

Please Specify Min. / Max. Size of the Sheet. (Length x Width x Thickness)

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Magnetic Lifters Category

कायमस्वरूपी लि

वापर : LIFTING DIES, MOULD, STEEL PLATES/BLOCKS

उचलण्याची क्षमता : किलोग्रॅम (किलो)

किमान ऑर्डरची मात्रा : 1

मापनाचे एकक : युनिट/युनिट

किंमत एकक : तुकडा/तुकडे

अट : नवीन

कायमस्वी इलेक्ट्र

वापर : LIFTING DIES, MOULD, STEEL PLATES/BLOCKS

उचलण्याची क्षमता : किलोग्रॅम (किलो)

किमान ऑर्डरची मात्रा : 1

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

अट : नवीन

ईपीएम प्लेट लिफ्टर

वापर : LIFTING DIES, MOULD, STEEL PLATES/BLOCKS

उचलण्याची क्षमता : किलोग्रॅम (किलो)

किमान ऑर्डरची मात्रा : 1

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

अट : नवीन

मॅग्नेटिक लिफटर

वापर : LIFTING DIES, MOULD, STEEL PLATES/BLOCKS

उचलण्याची क्षमता : किलोग्रॅम (किलो)

किमान ऑर्डरची मात्रा : 1

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

अट : नवीन