Electropermanent Round Chuck For Turning

Electropermanent Round Chuck For Turning Specification

- Thickness

- 100 mm

- Magnet Grade

- High-energy NdFeB

- Machine Type

- Lathe & Turning Machine

- Magnet Category

- Electropermanent Magnetic Chuck

- Composite

- Steel-Brass Laminate Surface

- Shape

- Round

- Application

- Precision Turning, Cylindrical Grinding

- Size

- Diameter ranges from 200 mm to 1500 mm

- Weight

- Varies with size (e.g. 65 kg for 350 mm )

- Color

- Metallic Grey

- Function

- Workpiece Holding with Electrical Activation

- Capacity

- Heavy-duty clamping for large workpieces

- Brand Required

- As Per Customer Specification

- Material

- Alloy Steel Body, Brass & Steel Top

- Operating Temperature

- Up to 80°C

- Cooling Method

- None (Dry Use)

- Surface Finish Accuracy

- ±15-20 microns

- Suitable Workpiece Thickness

- Minimum 8 mm

- Operating Voltage

- 110V DC

- Connection Type

- Electrical terminal box

- Safety Feature

- Permanent magnetic holding in power failure

- Control System

- Electronic External Controller

- Mounting Provision

- Center/Mounting Holes

- Release Time

- < 3 seconds

- IP Rating

- IP54

- Pole Pitch

- 10 mm Steel / 4 mm Brass

- Power Consumption

- Negligible after magnetization

- Holding Force

- Up to 120 N/cm²

Electropermanent Round Chuck For Turning Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 3 Days

About Electropermanent Round Chuck For Turning

Electropermanent Round Chuck For Turning

- Used in vertical and horizontal turning of plates

- Help to position and secure work pieces

For Heavy Turning

- Double magnet is available for heavy duty operations on seamless rolled rings, turning, flanges and machining plates

- Ensures ID, OD and face machining in one setup

Features:

- Detachable bayonet plug for power supply

- Poles are individually magnetized for full loading power

- Assembled with powerful magnets

- Clamp force is consistent & predictable

- No Heat is generated by integrating coil when magnet is activated

- Ability to withstand high temperature

- Perfect finish and excellent in strength

Technical Specifications:

| Sr. No. | Cat No. | Size (mm) |

| 1 | UL - 82101 | 300 x 100 H |

| 2 | UL - 82102 | 450 x 100 H |

| 3 | UL - 82103 | 500 x 100 H |

| 4 | UL - 82104 | 600 x 100 H |

| 5 | UL - 82105 | 1000 x 100 H |

| 6 | UL - 82106 | 1250 x 100 H |

| 7 | UL - 82107 | 1500 x 100 H |

| " ULTRA" VARIABLE CONTROL UNIT FOR ABOVE CHUCKS "ULTRA" EXTENSION BLOCK "ULTRA" EXTENSION JAWS (Movebal) | ||

Advanced Magnetic Clamping Technology

This electropermanent round chuck utilizes high-energy NdFeB magnets combined with a steel-brass laminate surface, providing strong and stable magnetic clamping. The power is only needed momentarily for activation or release, significantly reducing energy consumption and heat generation, making it both efficient and reliable for heavy-duty turning and cylindrical grinding operations.

Designed for Industrial Productivity & Safety

Built with operator safety and machine versatility in mind, the chucks permanent magnetic holding feature ensures uninterrupted clamping in the event of a power failure. Its heavy-duty construction accommodates large workpieces, and the electronic external controller offers precise operation with a release time of less than 3 secondsideal for high-throughput industrial environments.

FAQs of Electropermanent Round Chuck For Turning:

Q: How does the electropermanent round chuck ensure safety during power failures?

A: This chuck features permanent magnetic holding. If a power failure occurs, the magnetic force remains engaged and reliably secures the workpiece, minimizing risk and ensuring operator safety.Q: What is the recommended minimum workpiece thickness for effective clamping?

A: For optimal magnetic holding, workpieces should be at least 8 mm thick. Thinner materials could reduce the chucks efficiency and holding strength.Q: When should an electropermanent chuck be chosen over traditional magnetic or mechanical chucks?

A: Choose an electropermanent magnetic chuck when precision clamping, rapid activation/release, energy efficiency, and safety in power loss situations are requiredespecially in continuous or heavy-duty turning operations.Q: Where can this round chuck be mounted, and how is it installed?

A: The chuck comes with center or mounting holes, allowing it to be easily installed on lathe and turning machines. Mounting provisions are adaptable for various machine setups as per customer requirements.Q: What is the process of activating and releasing workpieces with this chuck?

A: Workpieces are clamped or released via an electronic external controller. Electrical power is used briefly to magnetize or demagnetize the chuck, with the release process typically taking less than 3 seconds.Q: How does the chucks composite steel-brass laminate surface benefit precision turning applications?

A: The steel-brass laminate ensures consistent magnetic distribution and minimizes heat, promoting exceptional surface finish accuracy within 15-20 micronscritical for high-precision turning and grinding tasks.Q: What maintenance or cooling does this unit require during operation?

A: No cooling system is needed, as it is designed for dry use and consumes negligible power after magnetization, resulting in minimal maintenance for continuous operation.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 3 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Magnetic Chuck Category

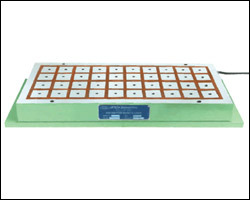

Multi Coil Micro Fine Pitch Magnetic Chucks

Price Range 5000.00 - 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue/Gray (as per finish)

Application : Other, Precision grinding, EDM and light milling operations

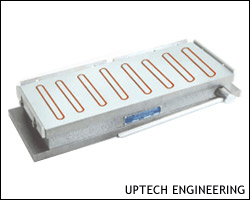

Electroperm Light Duty Chuck

Price Range 5000.00 - 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver with black magnetic strips

Material : High Quality Steel

Application : Other, Holding thin and small workpieces during grinding or light machining operations

EPM Chuck For Horizontal Machine

Price Range 5000.00 - 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Industrial Grey

Material : Mild Steel Body with Magnetic Top Plate

Application : Other, Precision Workholding for Milling and Grinding Machining Operations

Permanent Magnetic Chuck

Price Range 5000.00 - 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : White

Material : Carbon Steel

PLC Control : No