हà¥à¤µà¥ डà¥à¤¯à¥à¤à¥ सà¥à¤¥à¤¾à¤¯à¥ à¤à¥à¤à¤¬à¤à¥

हà¥à¤µà¥ डà¥à¤¯à¥à¤à¥ सà¥à¤¥à¤¾à¤¯à¥ à¤à¥à¤à¤¬à¤à¥ Specification

- जाडी

- 75 mm

- मशीन प्रकार

- Surface Grinder

- लोहचुंबक ग्रेड

- N52

- लोहचुंबक श्रेणी

- Permanent Magnetic Chuck

- अनुप्रयोग

- आकार

- 300mm x 150mm x 75mm (can vary as per requirement)

- वजन

- Approx. 32 kg (varies with size)

- रंग

- Metallic Grey

- कार्य

- Hold ferromagnetic workpieces securely

- क्षमता

- Heavy Duty

- ब्रँड आवश्यक

- As per requirement

- साहित्य

- High Quality Steel & Magnet

- Corrosion Resistance

- High

- Accuracy

- Within 0.005 mm on the top surface

- Cooling Type

- Dry & Wet applications

- Working Face Flatness

- Within 0.005 mm

- Operating Type

- Manual ON/OFF switch

- Rust Proof

- Yes

- Pole Pitch

- 14+4 mm or 12+3 mm, customized available

- Temperature Resistance

- Up to 80°C

- Holding Power

- 1200 N/100 cm²

हà¥à¤µà¥ डà¥à¤¯à¥à¤à¥ सà¥à¤¥à¤¾à¤¯à¥ à¤à¥à¤à¤¬à¤à¥ Trade Information

- Minimum Order Quantity

- 1 तुकडा

- पुरवठा क्षमता

- प्रति महिना

- वितरण वेळ

- दिवस

About हà¥à¤µà¥ डà¥à¤¯à¥à¤à¥ सà¥à¤¥à¤¾à¤¯à¥ à¤à¥à¤à¤¬à¤à¥

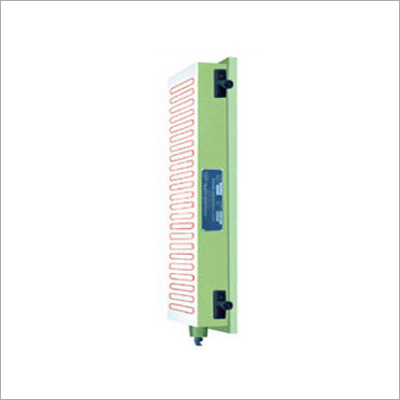

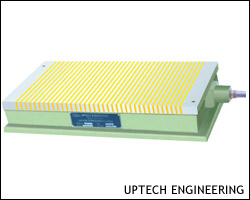

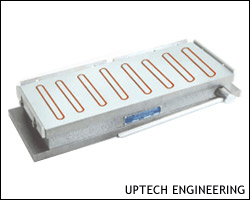

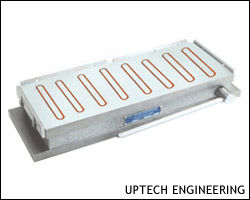

Achieving expertise since 1999, we have developed ourselves as a leading manufacturer, exporter and supplier of Ultra brand Heavy Duty Permanent Magnetic Chucks. Manufactured from excellent grade magnets and sophisticated techniques, these chucks are designed under the stern supervision of our professionals as per the standards penciled by the industry. Offered chucks are suitable for all types of surface grinding operations. Furthermore, the provided Ultra brand Heavy Duty Permanent Magnetic Chucks can be availed from us in distinct sizes and other specifications at rock bottom prices.

Features:

- Ability to withstand high temperature

- Perfect finish and excellent in strength

- Strong enough to combat high pressure

- Weather resistant and abrasion proof

- High electrical and thermal conductivity

- Dimensional accuracy leads to easy installation

Heavy Duty Permanent Magnetic Chucks

- PERMANENT MAGNETIC CHUCK (HEAVY DUTY)

- Holding device for surface grinding machine, Tool & cutter grinder, Spark erosion machines

- Accuracy as per IS : 4816 - 1987

- Assembled with powerful Magnets

- Poles individually magnetized for full loading power

- Magnetic pull is 40-70% more than IS specification

- Bottom plate has suitable extension to clamp on table

- Easy operated ON-OFF lever

Specification

| Size | 200 L x 100 W x 60 H |

| Usage/Application | Industrial |

| Shape | Rectangular |

| Magnet Grade | N35 |

| Brand | Ultra |

| Pole Pitch | 32 mm |

| Country of Origin | Made in India |

| Accuracy according to IS | 4816-1987 |

| Magnetic pull | 40% to 70% more than IS specification |

| Usage | Holding device for tool & cutter grinder, surface grinding machine and spark erosion machines |

| Pole Gap | 19 mm |

Technical Information:

| Sr.No. | Cat No. | Size | Ploe Gap (mm) | Pole Pitch (mm) |

| 1 | UL-70803 | 200 L x 100 W x 60 H | 16 | 32 |

| 2 | UL-70804 | 200 L x 150 W x 60 H | 19 | 32 |

| 3 | UL-70805 | 250 L x 150 W x 60 H | 19 | 35 |

| 4 | UL-70806 | 300 L x 150 W x 60 H | 19 | 35 |

| 5 | UL-70807 | 300 L x 200 W x 65 H | 19 | 35 |

| 6 | UL-70808 | 350 L x 150 W x 65 H | 19 | 35 |

| 7 | UL-70809 | 400 L x 150 W x 65 H | 19 | 35 |

| 8 | UL-70810 | 450 L x 150 W x 65 H | 19 | 35 |

| 9 | UL-70811 | 450 L x 200 W x 70 H | 19 | 35 |

| 10 | UL-70812 | 500 L x 200 W x 70 H | 19 | 35 |

| 11 | UL-70813 | 600 L x 200 W x 70 H | 19 | 35 |

| 12 | UL-70814 | 450 L x 250 W x 70 H | 19 | 35 |

| 13 | UL-70815 | 450 L x 300 W x 70 H | 19 | 35 |

| 14 | UL-70816 | 600 L x 250 W x 70 H | 19 | 35 |

| 15 | UL-70817 | 600 L x 300 W x 70 H | 19 | 35 |

| 16 | UL-70818 | 750 L x 250 W x 70 H | 19 | 35 |

Exceptional Clamping Force

The Permanent Magnetic Chuck boasts immense holding power per 100 cm, making it suitable for securing heavy-duty ferromagnetic workpieces during surface grinding, milling, EDM, and other precision operations. The robust N52 magnets and carefully engineered pole pitch contribute to reliable and uniform magnetic force distribution for improved machining efficiency.

High-Precision and Durability

Engineered for accuracy within 0.005 mm across the top surface, the chuck maintains exceptional flatness for precision machining. Crafted from premium steel and N52 magnets, it resists rust and corrosion, allowing use in both dry and wet environments. Its construction ensures long service life even under rigorous industrial conditions.

Flexible and Customizable Design

Available in a standard size of 300mm x 150mm x 75mm (with variations as required), these chucks can be tailored to specific shapes, brand requirements, and applications. Designed for surface grinders but well-adapted for various machine types, they support a wide range of industrial processes and project needs.

FAQs of Heavy Duty Permanent Magnetic Chucks:

Q: How does the manual ON/OFF switch operate on the Heavy Duty Permanent Magnetic Chuck?

A: The manual ON/OFF switch allows users to easily activate or deactivate the magnetic holding force, enabling quick setup and removal of workpieces without the need for external power, which enhances operator safety and efficiency.Q: What applications are these Permanent Magnetic Chucks suitable for?

A: They are engineered for surface grinding, milling, EDM, and precision machining of ferromagnetic workpieces in both dry and wet environments, making them versatile for a wide array of manufacturing and tooling operations.Q: When should a customized Magnetic Chuck be considered?

A: Custom chucks are ideal when you have unique size, shape, or brand requirements for your specific machine or workflow, ensuring optimal compatibility and holding performance for non-standard setups.Q: Where are these Heavy Duty Permanent Magnetic Chucks manufactured and supplied?

A: These chucks are manufactured, supplied, and exported from India, catering to both domestic and international markets as per the clients requirements.Q: What is the process for maintaining these chucks for maximum lifespan?

A: Routine cleaning of the working face, especially after wet operations, along with periodic inspection for wear or rust, will keep the chuck in optimal condition. The rustproof construction and high corrosion resistance simplify maintenance.Q: How does the chuck benefit precision machining operations?

A: With flatness and accuracy within 0.005 mm and a strong, consistent magnetic field, the chuck ensures stable holding of workpieces. This leads to higher machining accuracy, minimized vibration, and reduced setup times for critical tasks.Q: Can the chuck handle both dry and wet cooling applications effectively?

A: Yes, the design supports both dry and wet machining environments, providing reliable corrosion resistance and durability whether coolant is used or not.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Magnetic Chuck Category

रेडियल पोल इलेक्ट्रोपरम चुंबकीय

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

इलेक्ट्रोमॅग्नेटिक आय

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

आयताकृती चुं

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

कायमस्वरुपी च

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे