रà¥à¤¡à¤¿à¤¯à¤² पà¥à¤² à¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® à¤à¥à¤à¤¬à¤à¥à¤¯

रà¥à¤¡à¤¿à¤¯à¤² पà¥à¤² à¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® à¤à¥à¤à¤¬à¤à¥à¤¯ Specification

- लोहचुंबक श्रेणी

- Electroperm Magnetic Chuck

- मशीन प्रकार

- Surface Grinder / Rotary Table Machine

- लोहचुंबक ग्रेड

- Premium Rare Earth Magnets (Neodymium/Ferrite composite)

- आकार

- Diameter range: 200 mm to 1500 mm

- वजन

- Varies as per size (approx. 55 kg for 400 mm)

- रंग

- Metallic Grey

- कार्य

- Electroperm magnetic holding for circular part clamping

- ब्रँड आवश्यक

- As per client specification

- साहित्य

- Steel and Brass

- Pole Type

- Radial Poles

- Environmental Protection

- IP54 Grade

- Power Consumption

- Negligible, only during magnetization/demagnetization

- Min Thickness of Workpiece

- 10 mm

- Magnetic Field Depth

- Up to 15 mm

- Clamping Force

- Up to 140 N/cm²

- Work Surface Finish

- Precision Ground

- Cable Entry

- Side or Bottom entry as per requirement

- Heat Resistance

- Suitable for dry and wet machining options

- Operating Voltage

- 110/220 V AC/DC

- Poles Pitch

- 14 mm (Standard) / Custom on request

रà¥à¤¡à¤¿à¤¯à¤² पà¥à¤² à¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® à¤à¥à¤à¤¬à¤à¥à¤¯ Trade Information

- Minimum Order Quantity

- 1 तुकडा

- पुरवठा क्षमता

- प्रति महिना

- वितरण वेळ

- दिवस

About रà¥à¤¡à¤¿à¤¯à¤² पà¥à¤² à¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® à¤à¥à¤à¤¬à¤à¥à¤¯

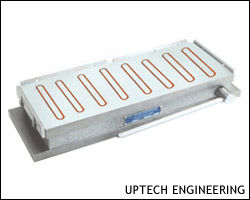

With a vision of catering specific requirements of our patrons, we offer Ultra brand Radial Pole Electroperm Magnetic Chucks. Offered chucks finds extensive usage in clamping application for tough cutting. These chucks can also be utilized in milling, grinding and machining centers. The provided chucks are manufactured under the strict vigilance of our experienced professionals by employing optimum quality magnets and innovative technology in conformity with set international standards. Apart from this, the offered Ultra brand Radial Pole Electroperm Magnetic Chucks can be availed from us in variegated specifications at pocket-friendly prices.

Features:

- Having anti-corrosive body

- Build with extra ordinary perfection

- Ability to withstand high temperature

- High tolerance and robust construction

- Can sustain harsh weather conditions

- High tensile strength makes it indestructible

Radial Pole Electroperm Magnetic Chuck

Item Code: SeriesUL-815

Features:

- Continuous Electricity is not required. 100% safe in used.

- Power for all poles transferred to ring / plates to hold the job firmly.

- Assembled with power full magnets. So heavy cut can taken

- Poles individually magnetized for full loading power.

Application

- Use in vertical and horizontals turning of lathes.

- Radially movable location blocks will help to position and secure work pieces. This is also necessary for clearance off the cutting tool or wheel.

Technical Specifications:

| Sr No | Cat No | Size (mm) |

| 1 | UL-81501 | 300 x 100 H |

| 2 | UL-81502 | 450 x 100 H |

| 3 | UL-81503 | 500 x 100 H |

| 4 | UL-81504 | 600 x 100 H |

| 5 | UL-81505 | 800 x 100 H |

| 6 | UL-81506 | 1000 x 100 H |

| 7 | UL-81507 | 1250 x 115 H |

| Ultra Variable Control Unit for above chucks | 1500 x 115 H | |

| Ultra Extension Block | ON REQUEST | |

| Ultra Extension Jaws (Moveable) | ON REQUEST |

Other Information

- Minimum Order Quantity: 1 Set

- Delivery Time: 1Month

Unmatched Clamping Performance

Benefit from powerful and uniform clamping with up to 140 N/cm force, ideal for holding circular parts securely. The radial pole design enhances magnetic field penetration up to 15 mm, ensuring a firm grip suitable for both light and heavy-duty machining tasks. It provides exceptional stability even with thin or medium-thickness workpieces.

Versatile Design for Varied Applications

Available in round/circular shapes, with diameter options from 200 mm to 1500 mm and side or bottom cable entry as per your requirements, these chucks are tailored for flexibility. Precision-ground work surfaces and customizable pole pitch allow seamless integration with different grinder and rotary table machines. They are suited for both dry and wet machining environments.

Energy-Efficient and Reliable

These Electroperm chucks consume power only during magnetization or demagnetization, ensuring minimal energy use and operational cost savings. Once magnetized, they maintain holding force without continuous electrical power, offering safety and reliability in industrial environments. The robust steel and brass construction further boosts longevity and performance.

FAQs of Radial Pole Electroperm Magnetic Chucks:

Q: How does a Radial Pole Electroperm Magnetic Chuck operate?

A: The chuck operates by passing a brief electrical pulse (110/220 V AC/DC) which magnetizes or demagnetizes the rare earth magnet array inside. It then retains magnetic holding without the need for continuous power, making it energy-efficient and safe.Q: What types of machines is this magnetic chuck suitable for?

A: It is ideal for use on surface grinders and rotary table machines, particularly when clamping circular workpieces. The flexible design and high clamping force ensure reliable performance across various industrial applications.Q: When should I use this magnetic chuck?

A: Use this chuck whenever secure and uniform holding of circular or round ferrous parts is essential, especially for precision grinding or rotary table machining. Its suitable for both wet and dry machining processes.Q: Where is the cable entry point located?

A: The chuck offers either side or bottom cable entry options, allowing you to match the installation requirements of your specific machine setup.Q: What is the minimum workpiece thickness that can be clamped?

A: The minimum recommended thickness for effective magnetic clamping is 10 mm, ensuring sufficient holding force and machining precision.Q: How is the work surface finished?

A: The work surface is precision ground, which promotes accurate part placement and optimal machining results while minimizing the risk of surface damage.Q: What are the main benefits of using this radial pole chuck?

A: Key benefits include strong and stable clamping (up to 140 N/cm), negligible power consumption post-activation, suitability for a wide size range (200-1500 mm diameter), and durability provided by premium magnets and robust construction.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Magnetic Chuck Category

मल्टी कॉइल मायक्रो फाइन पिच चु

जाडी : 60 mm

ब्रँड आवश्यक : Custom/Universal

वजन : Approx. 22 kg (varies with size)

किंमत एकक : तुकडा/तुकडे

मापनाचे एकक : तुकडा/तुकडे

अनुप्रयोग : ,

टर्निंगसाठी इलेक्ट्रोपरमेंट

जाडी : 100 mm

ब्रँड आवश्यक : As Per Customer Specification

वजन : Varies with size (e.g. 65 kg for 350 mm Ø)

किंमत एकक : तुकडा/तुकडे

मापनाचे एकक : तुकडा/तुकडे

अनुप्रयोग : ,

इलेक्ट्रोपरम हेवी ड्यूटी

जाडी : Approximately 100 mm

ब्रँड आवश्यक : Electroperm

वजन : Varies by size (approx. 60 kg for 300x150 mm)

किंमत एकक : तुकडा/तुकडे

मापनाचे एकक : तुकडा/तुकडे

अनुप्रयोग : ,

हेवी ड्यूटी स्थायी चुंबकी

जाडी : 75 mm

ब्रँड आवश्यक : As per requirement

वजन : Approx. 32 kg (varies with size)

किंमत एकक : तुकडा/तुकडे

मापनाचे एकक : तुकडा/तुकडे

अनुप्रयोग : ,