à¤à¥à¤·à¥à¤¤à¤¿à¤ मशà¥à¤¨à¤¸à¤¾à¤ ॠà¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® à¤à¥à¤à¤¬à¤à¥à¤¯

à¤à¥à¤·à¥à¤¤à¤¿à¤ मशà¥à¤¨à¤¸à¤¾à¤ ॠà¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® à¤à¥à¤à¤¬à¤à¥à¤¯ Specification

- लोहचुंबक ग्रेड

- N52 rare earth alloy

- जाडी

- 80 mm

- मशीन प्रकार

- Horizontal milling and grinding machine

- लोहचुंबक श्रेणी

- Electroperm hybrid permanent

- संमिश्र

- अनुप्रयोग

- आकार

- 300 x 600 mm (customizable sizes available)

- वजन

- Approx. 75 kg

- रंग

- Dark metallic/black

- ब्रँड आवश्यक

- Yes

- साहित्य

- Steel with magnetic core

à¤à¥à¤·à¥à¤¤à¤¿à¤ मशà¥à¤¨à¤¸à¤¾à¤ ॠà¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® à¤à¥à¤à¤¬à¤à¥à¤¯ Trade Information

- Minimum Order Quantity

- 1 तुकडा

- पुरवठा क्षमता

- प्रति महिना

- वितरण वेळ

- दिवस

About à¤à¥à¤·à¥à¤¤à¤¿à¤ मशà¥à¤¨à¤¸à¤¾à¤ ॠà¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® à¤à¥à¤à¤¬à¤à¥à¤¯

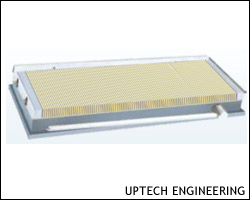

Electroperm Magnetic Chucks For Horizonatal Machine

Since our inception in 1999, we have been employing our best efforts in manufacturing, supplying and exporting a comprehensive range of Ultra brand Electroperm Magnetic Chucks For Horizontal Machine. Being a client-oriented firm, these chucks are manufactured with premier-grade metals that helps in ensuring their excellent magnetic properties. Magnetic properties are developed in these chucks by applying electricity so as to ensure their wide use for precision machining and holding ferro-magnetic work pieces. Offered Ultra brand Electroperm Magnetic Chucks are completely fault-free and acclaimed by clients for their lightweight, compact & portable design and fine finishing.

EPM CHUCK is designed in such a way that it is very useful for Horizontal machining centers. It is also useful in conventional machining for Horizontal milling operation.

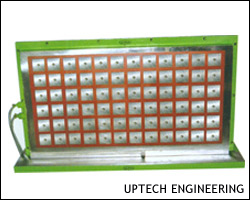

As Electro Permanent Magnetic (EPM) Principle is used

- Continues Electrically is not required.

- Easily intergrated with pallet clamping

- Manufactured as per customer requirement

Reliable Clamping for Precise Machining

Electroperm Magnetic Chucks are engineered for horizontal milling and grinding machines, designed to deliver consistent, accurate workpiece clamping. With minimal chuck face runout and strong holding force, these chucks ensure smooth, precise operations even during demanding tasks. The failsafe design and robust construction contribute to a reliable machining environment, enhancing both safety and efficiency in industrial settings.

Advanced Magnetic Technology with Safety Features

By leveraging hybrid Electroperm technology, these chucks deliver powerful, stable clamping of ferromagnetic materials. The digital electronic controller allows easy activation while the residual magnetism post-deactivation remains below 1.5%, ensuring rapid, hassle-free workpiece shifts. The fail-safe magnetization process retains holding power during unexpected power interruptions, maximizing operational safety for operators.

Durability and Compatibility for Industrial Demands

Constructed from a magnetic alloy and steel composite, the chuck is fully sealed, providing excellent resistance to coolants and oils. Removable end stop blocks enable accurate workpiece alignment, while versatile mounting holes cater to secure fixture on a variety of horizontal machine tables. Suitable exclusively for ferromagnetic materials, it is an ideal solution for a broad spectrum of horizontal machining applications.

FAQs of Electroperm Magnetic Chucks For Horizontal Machine:

Q: How is the Electroperm Magnetic Chuck for horizontal machines operated and controlled?

A: This chuck is managed using a digital electronic controller that allows for swift magnetization and demagnetization using a standard 220V AC/50Hz power supply. The systems modern design simplifies operation, bolstered by failsafe safety features.Q: What types of materials are compatible with this chuck?

A: The Electroperm Magnetic Chuck is engineered specifically for ferromagnetic materials. Non-ferrous or non-magnetic items are not suitable for clamping with this device.Q: When should I consider using an Electroperm Magnetic Chuck instead of traditional mechanical clamps?

A: Opt for this magnetic chuck when precision, rapid setup, and easy workpiece adjustment are essential, especially in horizontal milling or grinding applications. It excels at holding flat or round ferromagnetic workpieces securely without the risk or hassle of mechanical clamping systems.Q: Where can the Electroperm Magnetic Chuck be installed?

A: It is designed for mounting on horizontal milling and grinding machines, using the provided mounting holes for secure fixture to machine tables. Its seal and insulation facilitate use in environments exposed to coolants and oils.Q: What is the process for aligning workpieces on the chuck?

A: Removable lateral end stop blocks assist in accurate alignment of workpieces on the chuck face, ensuring consistent and repeatable positioning for each operation.Q: How does the failsafe operation benefit users during power interruptions?

A: With failsafe technology, the Electroperm Magnetic Chuck maintains its magnetic holding force during power outages, protecting the workpiece and machinery and minimizing the risk of accidents during unexpected power loss.Q: What maintenance is required for the Electroperm Magnetic Chuck?

A: Routine inspections to ensure sealing integrity and cleaning the chuck face to prevent debris build-up are advised. Thanks to its robust construction and minimal residual magnetism, the chuck requires little ongoing maintenance.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Magnetic Chuck Category

मल्टी कॉइल मायक्रो फाइन पिच चु

मापनाचे एकक : तुकडा/तुकडे

किंमत किंवा किंमत श्रेणी : INR

किमान ऑर्डरची मात्रा : 1

किंमत एकक : तुकडा/तुकडे

आकार : 250 mm x 150 mm (Other sizes available on request)

रंग : Blue/Gray (as per finish)

टर्निंगसाठी इलेक्ट्रोपरमेंट

मापनाचे एकक : तुकडा/तुकडे

किंमत किंवा किंमत श्रेणी : INR

किमान ऑर्डरची मात्रा : 1

किंमत एकक : तुकडा/तुकडे

आकार : Diameter ranges from 200 mm to 1500 mm

रंग : Metallic Grey

इलेक्ट्रोपरम हेवी ड्यूटी

मापनाचे एकक : तुकडा/तुकडे

किंमत किंवा किंमत श्रेणी : INR

किमान ऑर्डरची मात्रा : 1

किंमत एकक : तुकडा/तुकडे

आकार : Standard sizes: 300 x 150 mm, 400 x 200 mm, Custom Sizes Available

रंग : Metallic Grey with Black Details

मायक्रो फाइन पिच इलेक्ट्रोपरम मॅग्नेट

मापनाचे एकक : तुकडा/तुकडे

किंमत किंवा किंमत श्रेणी : INR

किमान ऑर्डरची मात्रा : 1

किंमत एकक : तुकडा/तुकडे

आकार : 150 mm x 300 mm to 600 mm x 1000 mm (custom sizes available)

रंग : Metallic Grey/Black