à¤à¥à¤·à¥à¤¤à¤¿à¤ मशà¥à¤¨à¤¸à¤¾à¤ ॠà¤à¤ªà¥à¤à¤® à¤à¤

à¤à¥à¤·à¥à¤¤à¤¿à¤ मशà¥à¤¨à¤¸à¤¾à¤ ॠà¤à¤ªà¥à¤à¤® à¤à¤ Specification

- लोहचुंबक श्रेणी

- Electro Permanent Magnetic

- लोहचुंबक ग्रेड

- Industrial Grade

- जाडी

- 85 mm

- मशीन प्रकार

- Horizontal Machining Centers

- अनुप्रयोग

- आकार

- Available from 300 x 600 mm up to 600 x 1200 mm

- वजन

- Varies by size, approx. 120 kg (for 300 x 600 mm)

- रंग

- Industrial Grey

- कार्य

- Securely holds ferrous job on horizontal machines using magnetic force

- ब्रँड आवश्यक

- Customized as per customer requirement

- साहित्य

- Mild Steel Body with Magnetic Top Plate

à¤à¥à¤·à¥à¤¤à¤¿à¤ मशà¥à¤¨à¤¸à¤¾à¤ ॠà¤à¤ªà¥à¤à¤® à¤à¤ Trade Information

- Minimum Order Quantity

- 1 तुकडा

- पुरवठा क्षमता

- प्रति महिना

- वितरण वेळ

- दिवस

About à¤à¥à¤·à¥à¤¤à¤¿à¤ मशà¥à¤¨à¤¸à¤¾à¤ ॠà¤à¤ªà¥à¤à¤® à¤à¤

- Suitable for rough block machining applications

- Requires very less maintenance and ensures long-functional life

- Provided in distinct technical specifications and models

- Perfect and fast polishing machining speed with consistent performance

- Easy to operate and work with great efficiency

- Less manual interface with maximum output

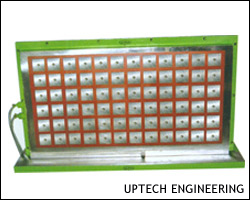

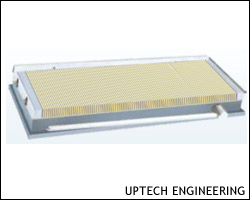

- EPM Chuck For Horizontal Machine

- Designed for installation in horizontal machining centers

- Also suitable for use in conventional machines that are designed for horizontal milling operation

- Built-in electro permanent magnetic (EPM) Does not requires continues electrically

- Easy to integrate in combination with pallet clamping

- Manufactured in customized designs as per requirements of clients

Advanced Magnetic Clamping Technology

Utilizing electro permanent magnetic technology, this chuck ensures exceptional holding force with minimal residual magnetism (<6% after demagnetization). The safety interlock feature and remote control streamline workflow while enhancing operator security. Designed with a robust mild steel body and a hardened magnetic top plate, this product is built for durability even under the rigorous conditions of industrial machining.

Application-specific Design

Developed for horizontal machining centers, the EPM Chuck is specifically tailored for precision workholding in milling and grinding applications. Thanks to a customizable size range (from 300 600 mm up to 600 1200 mm) and application-driven features, it seamlessly adapts to various job requirements, providing flexibility and reliability to manufacturers, dealers, and exporters.

FAQs of EPM Chuck For Horizontal Machine:

Q: How does the remote electrical control with safety interlock work on the EPM Chuck?

A: The remote electrical control allows users to engage or disengage the magnetic clamping from a safe distance, ensuring operator convenience. The built-in safety interlock prevents accidental activation or release, providing an additional layer of protection during machining operations.Q: What materials and job sizes can the EPM Chuck accommodate?

A: This magnetic chuck is designed for clamping ferrous workpieces suitable for horizontal milling and grinding. It is available in sizes ranging from 300 600 mm to 600 1200 mm, and its robust construction easily supports various weights and dimensions within this range.Q: When is it beneficial to use an electro permanent magnetic chuck over traditional workholding solutions?

A: Electro permanent magnetic chucks offer superior clamping stability, reduced setup time, and consistent holding force without continuous power consumption. They are especially advantageous in environments where rapid, safe, and reliable workpiece handling is required for precision machining.Q: Where can the EPM Chuck be installed, and is it resistant to coolant exposure?

A: This chuck is specifically built for installation on horizontal machining centers. Its coolant-resistant design ensures reliable operation and longevity even in environments with significant coolant exposure during milling or grinding processes.Q: What is the process for clamping and unclamping workpieces with this chuck?

A: Clamping is initiated remotely by activating the control, which magnetically secures the workpiece. Unclamping is performed the same way. Power is used only during these actions, contributing to energy efficiency while ensuring strong, consistent holding between cycles.Q: How does the low residual magnetism benefit my machining applications?

A: The low residual magnetism (<6% after demagnetization) ensures that workpieces are released cleanly after machining, reducing the risk of leftover magnetic attraction and making part removal easy and safe.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Magnetic Chuck Category

इलेक्ट्रोपरम हेवी ड्यूटी

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

लोहचुंबक श्रेणी : Electroperm Magnetic

रंग : Metallic Grey with Black Details

क्षैतिज मशीनसाठी इलेक्ट्रोपरम चुंबकीय

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

लोहचुंबक श्रेणी : Electroperm hybrid permanent

रंग : Dark metallic/black

मायक्रो फाइन पिच इलेक्ट्रोपरम मॅग्नेट

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

लोहचुंबक श्रेणी : Electroperm (Electro Permanent Magnet)

रंग : Metallic Grey/Black

रेडियल पोल इलेक्ट्रोपरम चुंबकीय

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

लोहचुंबक श्रेणी : Electroperm Magnetic Chuck

रंग : Metallic Grey