मायà¤à¥à¤°à¥ फाà¤à¤¨ पिठà¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® मॠà¤à¥à¤¨à¥à¤

मायà¤à¥à¤°à¥ फाà¤à¤¨ पिठà¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® मॠà¤à¥à¤¨à¥à¤ Specification

- लोहचुंबक श्रेणी

- Electroperm (Electro Permanent Magnet)

- जाडी

- 75 mm (standard), custom thickness on request

- मशीन प्रकार

- Surface Grinder, EDM, Milling Machine, CNC Machines

- अनुप्रयोग

- आकार

- 150 mm x 300 mm to 600 mm x 1000 mm (custom sizes available)

- वजन

- Varies by size, e.g., approx. 32 kg for 300x600 mm

- रंग

- Metallic Grey/Black

- क्षमता

- High holding capacity for small and thin ferromagnetic components

- ब्रँड आवश्यक

- As per customer requirement

- साहित्य

- Steel body with solid top plate

- Operating Temperature

- Max 80°C continuous

- Accuracy

- Parallelism and flatness within ±0.005 mm

- Switching

- Electronic control for ON/OFF operation, no residual magnetism

- Surface Finish

- Precision ground to tight tolerances

- Accessories

- Control unit and cable supplied as standard

- Pole Pitch

- 2 mm to 4 mm (Micro Fine Pitch)

- Power Consumption

- Low energy required; energy needed only during switching

- Polarity

- Double magnet system with high flux density

मायà¤à¥à¤°à¥ फाà¤à¤¨ पिठà¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® मॠà¤à¥à¤¨à¥à¤ Trade Information

- Minimum Order Quantity

- 1 तुकडा

- पुरवठा क्षमता

- प्रति महिना

- वितरण वेळ

- दिवस

About मायà¤à¥à¤°à¥ फाà¤à¤¨ पिठà¤à¤²à¥à¤à¥à¤à¥à¤°à¥à¤ªà¤°à¤® मॠà¤à¥à¤¨à¥à¤

Features:

- Continuous electricity is not required

- Power for all poles transferred to ring I plates to hold the job firmly

- Assembled with power full magnets

- Poles individually magnetized for full loading power

- Highly resistant to bad weather

- Indestructible by high pressure

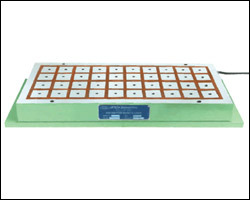

Fine Pitch Electroperm Magnetic Chucks

- Eliminates the use of traditional clamping methods in CNC machining center

- Heavy to light milling for work pieces

- Fine Pitch (1 + 0.5) that makes it suitable to hold very thin & small jobs

- Poles individually magnetized for full loading power

- Ensures excellent magnetic grip

- Equipped with easy operated ON-OFF lever

- Help to dampen vibrations, resulting in longer tool life

| Sr. No. | Cat No. | Size (mm) | Pole Pitch (mm) |

| 1 | UL 72101 | 250 L x 150 W x 60 H | 1.5 |

| 2 | UL 72102 | 300 L x 150 W x 60 H | 1.5 |

| 3 | UL 72103 | 350 L x 150 W x 60 H | 1.5 |

| 4 | UL 72104 | 400 L x 150 W x 60 H | 1.5 |

| 5 | UL 72105 | 450 L x 150 W x 60 H | 1.5 |

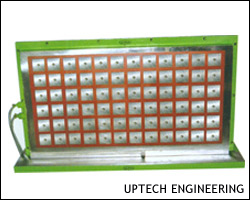

Ultimate Precision for Delicate Workpieces

Micro Fine Pitch Electroperm Magnetic Chucks excel in handling small and thin ferromagnetic parts, providing high holding strength and precision. Their micro-fine pole pitch (24 mm) enables perfect support for delicate components, ensuring superior machining results. The precision-ground surface and tight tolerances maintain consistent parallelism and flatness, crucial for high-accuracy applications in grinding, EDM, and milling.

Efficient and Reliable Operation

Equipped with an electronic control unit, these chucks offer effortless ON/OFF switching, eliminating residual magnetism. The energy-efficient design requires power only during phase changes, helping reduce operational costs. Their solid steel body and high-quality construction allow for continuous operation at temperatures up to 80C, providing lasting reliability across surface grinders, CNC machines, EDM, and milling setups.

FAQs of Micro Fine Pitch Electroperm Magnetic Chucks:

Q: How does the electronic switching mechanism benefit users of Electroperm Magnetic Chucks?

A: The electronic switching mechanism allows for easy ON/OFF operation, requiring power solely during the transition, which increases energy efficiency. This also ensures there is no residual magnetism left on the chuck, simplifying workpiece removal and improving safety during precision operations.Q: What is the advantage of micro fine pole pitch in magnetic chucks?

A: A micro fine pole pitch, ranging from 2 mm to 4 mm, delivers maximum holding force especially for small and thin ferromagnetic components, enabling secure and stable fixture during intricate processes such as precision grinding, light milling, and EDM work.Q: When should I choose a custom size or thickness for my magnetic chuck?

A: Custom sizes or thicknesses should be selected when standard dimensions (example: 75 mm thickness, 150x300 mm up to 600x1000 mm) do not align with your specific machine or application needs. Tailored options ensure optimal coverage and performance for unique workpiece or machine setups.Q: Where are Micro Fine Pitch Electroperm Magnetic Chucks commonly used?

A: These chucks are widely used in machining environments such as surface grinders, EDM systems, milling machines, and CNC machines across industries that require high-precision machining and workholding for small or intricate components.Q: What process is involved in operating these chucks for accurate workholding?

A: Place the workpiece on the chuck, then activate the chuck using the supplied control unit and cable. The double magnet system secures the component with high flux density. Precise machining or grinding can proceed, ensuring outstanding flatness and parallelism. Once complete, switch the chuck off electronically for easy workpiece removal.Q: Can these magnetic chucks handle continuous operations at elevated temperatures?

A: Yes, the chucks are constructed to function reliably in environments up to 80C continuous operating temperature, making them suitable for demanding machining tasks and prolonged operation periods.Q: What benefit does the double magnet system with high flux density provide?

A: The double magnet system amplifies flux density, resulting in a higher holding capacity and more secure clamping, especially for challenging, thin, or small ferromagnetic partsensuring stable machining and enhanced precision in every operation.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Magnetic Chuck Category

इलेक्ट्रोपरम लाइट ड्यूटी

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

किमान ऑर्डरची मात्रा : 1

साहित्य : High Quality Steel

लोहचुंबक श्रेणी : Electroperm

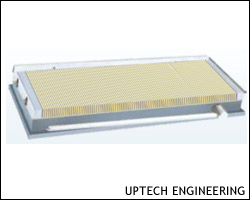

हेवी ड्यूटी स्थायी चुंबकी

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

किमान ऑर्डरची मात्रा : 1

साहित्य : High Quality Steel & Magnet

लोहचुंबक श्रेणी : Permanent Magnetic Chuck

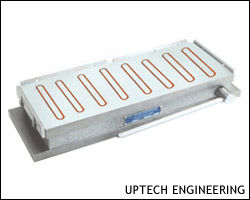

क्षैतिज मशीनसाठी इलेक्ट्रोपरम चुंबकीय

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

किमान ऑर्डरची मात्रा : 1

साहित्य : Steel with magnetic core

लोहचुंबक श्रेणी : Electroperm hybrid permanent

रेडियल पोल इलेक्ट्रोपरम चुंबकीय

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

किंमत एकक : तुकडा/तुकडे

किमान ऑर्डरची मात्रा : 1

साहित्य : Steel and Brass

लोहचुंबक श्रेणी : Electroperm Magnetic Chuck