मलà¥à¤à¥ à¤à¥à¤à¤² मायà¤à¥à¤°à¥ फाà¤à¤¨ पिठà¤à¥

मलà¥à¤à¥ à¤à¥à¤à¤² मायà¤à¥à¤°à¥ फाà¤à¤¨ पिठà¤à¥ Specification

- लोहचुंबक श्रेणी

- Permanent Magnetic Chuck

- लोहचुंबक ग्रेड

- NdFeB (Neodymium Iron Boron)

- मशीन प्रकार

- Surface Grinder, Milling Machine

- जाडी

- 60 mm

- अनुप्रयोग

- आकार

- 250 mm x 150 mm (Other sizes available on request)

- वजन

- Approx. 22 kg (varies with size)

- रंग

- Blue/Gray (as per finish)

- कार्य

- Workholding and positioning during fine machining

- ब्रँड आवश्यक

- Custom/Universal

- क्षमता

- High magnetic holding force for secure clamping of small and thin workpieces

मलà¥à¤à¥ à¤à¥à¤à¤² मायà¤à¥à¤°à¥ फाà¤à¤¨ पिठà¤à¥ Trade Information

- Minimum Order Quantity

- 1 तुकडा

- पुरवठा क्षमता

- प्रति महिना

- वितरण वेळ

- दिवस

- मुख्य देशांतर्गत बाजार

- सर्व भारत

- प्रमाणपत्रे

- ISO9001:2015

About मलà¥à¤à¥ à¤à¥à¤à¤² मायà¤à¥à¤°à¥ फाà¤à¤¨ पिठà¤à¥

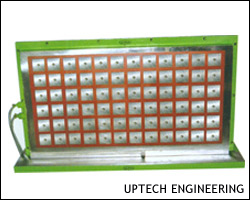

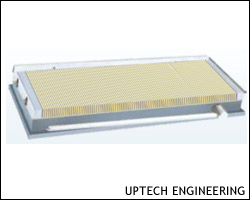

Equipped with latest technology and having a strong ethical background, we are able to offer our clients good quality Ultra brand Multi Coil Micro Fine Pitch Magnetic Chucks. These chucks are efficiently manufactured with immense care by utilizing superior quality magnets and efficient machinery. Sturdy in design, the provided chucks are highly acclaimed in surface grinding machines and suitable to hold thin & small jobs. Also, the offered Ultra brand Multi Coil Micro Fine Pitch Magnetic Chucks can be accessed from us in diverse specifications at industry leading rates.

Features:

- Has tough construction and can withstand high pressure

- Highly resilient to harsh conditions

- Perfectly finished that leads to smooth edges

- Easy to install due to its accurate dimensions

- Superior hardness and resistance to abrasion

- Provided in smooth surface finish with no roughness

Multi Coil Micro Fine Pitch Magnetic Chucks

- Multi-Coil Micro Fine Pitch Electro Magnetic Chuck

- Each pole possesses separate coil

- Even & strong magnetic flux

- Accuracy in compliance with IS:8710-1978

- Magnetic pull is 30% to 50% more than IS specification

- Fine Pitch (1 + 0.5) which makes it perfect to hold very small & thin jobs

- Mag-D-Mag with variable control unit ensures neutralize residual magnetism

- Variable power supply supports alignment and removing of warpages of thin jobs

- Tested for slippering force, electrical & demagnetizing tests, waterproof test and temperature rise test

- High quality and standard electrical accessories

- Special chucks for individual requirement

Technical Specifications:

| Sr. No. | Cat No. | Size (mm) | Pole Gap (mm) |

| 1 | UL-72201 | 450 L x 150 W x 100 H | 1.5 |

| 2 | UL-72202 | 450 L x 200 W x 100 H | 1.5 |

| 3 | UL-72203 | 500 L x 200 W x 100 H | 1.5 |

| 4 | UL-72204 | 600 L x 250 W x 100 H | 1.5 |

| 5 | UL-72205 | 750 L x 250 W x 100 H | 1.5 |

| 15A. | "ULTRA" MAG D- MAG WITH VARIABLE CONTROL UNIT | 2 Amp. | |

| | | | |

High Performance and Secure Clamping

The use of NdFeB permanent magnets ensures robust magnetic holding strength, ideal for small or thin ferrous workpieces. This enhances clamping security, facilitating high-precision results even during delicate machining tasks like EDM or fine grinding.

Versatile Application and Customization

Suitable for surface grinders and milling machines, the Multi Coil Micro Fine Pitch Magnetic Chuck fits seamlessly into a variety of manufacturing environments. While the standard size is 250 mm x 150 mm, custom dimensions can be supplied to meet specific project requirements.

Durability and Build Quality

Manufactured with quality materials and a 60 mm thickness, this magnetic chuck is designed for consistent stability and longevity. The blue or gray finish not only improves aesthetics but also resists wear in rigorous industrial settings.

FAQs of Multi Coil Micro Fine Pitch Magnetic Chucks:

Q: How does the Multi Coil Micro Fine Pitch Magnetic Chuck enhance workholding stability?

A: By utilizing high-strength NdFeB magnets and a fine pole pitch, this chuck delivers a powerful and uniform magnetic force. This secures even the smallest or thinnest workpieces, reducing movement during precision grinding, EDM, or light milling.Q: What is the main benefit of using a micro fine pitch design in this magnetic chuck?

A: The micro fine pitch offers more magnetic poles per surface area, providing superior grip and stability to thin or small workpieces, which ensures excellent machining accuracy and prevents deformation or slippage.Q: Where can this magnetic chuck be installed?

A: It is designed for use on surface grinders, milling machines, or EDM equipment in machine shops, tool rooms, and manufacturing plants seeking precise and reliable workholding.Q: When should I consider ordering a custom-sized chuck?

A: If your application involves workpieces or machine tables outside the standard 250 mm x 150 mm dimension, you can request custom sizes to best match your operational needs and ensure maximum magnetic coverage.Q: What is the process for using this chuck in daily machining operations?

A: After securely mounting the chuck on your machine table, simply position the workpiece atop the magnetic surface and activate the magnetization lever. Once activated, the strong magnetic field holds your workpiece firmly throughout the machining cycle.Q: Can this magnetic chuck be used for heavy-duty cutting operations?

A: This chuck is optimized for precision grinding, EDM, and light milling operations. For heavy-duty or high-impact machining, consider consulting the supplier for a suitable workholding solution.

- Minimum Order Quantity

- Supply Ability

- Delivery Time

- Main Domestic Market

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Magnetic Chuck Category

इलेक्ट्रोपरम हेवी ड्यूटी

किमान ऑर्डरची मात्रा : 1

किंमत एकक : तुकडा/तुकडे

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

आकार : Standard sizes: 300 x 150 mm, 400 x 200 mm, Custom Sizes Available

साहित्य : Steel and Permanent Magnets

क्षैतिज मशीनसाठी इलेक्ट्रोपरम चुंबकीय

किमान ऑर्डरची मात्रा : 1

किंमत एकक : तुकडा/तुकडे

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

आकार : 300 x 600 mm (customizable sizes available)

साहित्य : Steel with magnetic core

क्षैतिज मशीनसाठी ईपीएम चक

किमान ऑर्डरची मात्रा : 1

किंमत एकक : तुकडा/तुकडे

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

आकार : Available from 300 x 600 mm up to 600 x 1200 mm

साहित्य : Mild Steel Body with Magnetic Top Plate

मायक्रो फाइन पिच इलेक्ट्रोपरम मॅग्नेट

किमान ऑर्डरची मात्रा : 1

किंमत एकक : तुकडा/तुकडे

किंमत किंवा किंमत श्रेणी : INR

मापनाचे एकक : तुकडा/तुकडे

आकार : 150 mm x 300 mm to 600 mm x 1000 mm (custom sizes available)

साहित्य : Steel body with solid top plate